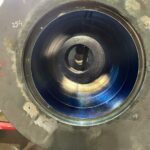

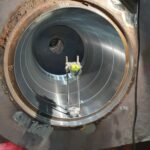

Mobile Conical Boring

Conical boring on site

De Wiel Services has a range of machines for conical internal boring on site. These activities are often carried out on large rudders in shipping. The connection between rudder blade and shaft is in most cases a surface press connection with a conicity of 1:10 or 1:15. By means of a blueprint, it is determined after the machining whether the surface degree of 100% has been achieved.

6 reasons for deciding to opt for on-site machining are:

Your product must meet a high quality standard in terms of dimensions

Your product cannot be machined in a machine factory

Your product is too big and heavy to transport by road

You think the waiting times at the machine factory are too long

You want to achieve the delivery time of your product within the set time

You would like to continue working on your own product during on-site machining

In that case, choose “De Wiel Services World Wide On Site Machining”

This implies:

Professional engineers

Optimal quality

Smooth turnaround time

Friendly services

Customer-oriented thinking

VCA certified

No nonsense

Our specialists and advanced machine tools are able to offer complicated on-site machining solutions in industrial environments all over the world. On-site machining can avoid the high costs associated with machine removal, transport, reassembly and machine downtime.

Is a standard solution not available? Then we look for a solution together with our customers. Our years of experience and craftsmanship ensure that we can provide specialist services.

Line drilling is unique. We can line drilling over a distance of up to 50 meters.

We are a down-to-earth company. We don’t promise you mountains of gold and we don’t put ourselves on a pedestal. We’re just doing our job. We do this well, quickly and at a fair price.