Propeller shaft installation

De Wiel Services Alignment is specialised in identifying problems to the propeller shaft installation. In order to keep propeller shaft installations running responsibly and safely, they require regular maintenance. De Wiel Services Alignment is able to identify various problems related to the propeller shaft installation.

Problems with the propeller shaft installation may become apparent during maintenance. Problems can also arise during the voyage. In most cases the problem is caused by poor maintenance of the propeller shaft installation.

By checking the stern tube, De Wiel Services Alignment can identify extensively the problems at various points, such as:

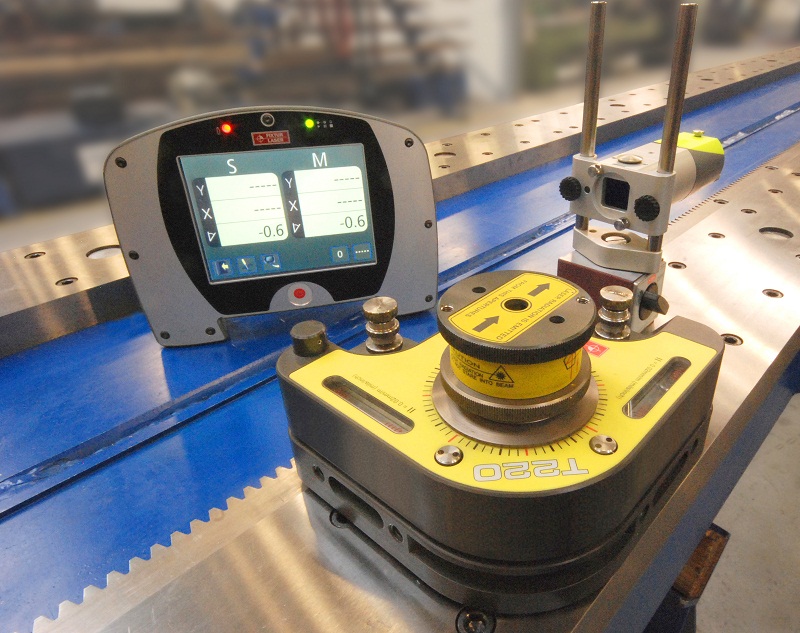

- Straightness of the stern tube with the bearing bushes, by carrying out a laser alignment.

- Straightness of the stern tube without the bearing bushes, by carrying out a laser alignment

- Measure the ovality of the positions where the bearing bushes are located.

- Measure the taper of the position where the bearing bushes are located.

- Determine the position of the stern tube in relation to the gearbox, by carrying out a laser alignment.

- Determine the position of the stern tube sleeve in relation to the nozzle.

- Determine the position of the stern tube sleeve in relation to the motor and gearbox foundation.

De Wiel Services Alignment can check the stern tube sleeve on all types of stern tube sleeve systems, such as oil lubricated stern tubes, water lubricated stern tubes, and grease lubricated stern tubes.

For a propeller shaft installation to rotate flawlessly, it is important to regularly check the alignment of the stern tube during maintenance, by inspecting the stern tube.

De Wiel Services Alignment has almost 50 years’ experience in the field of:

- Checking the stern tube;

- Inspecting the stern tube;

- Measuring the propeller shaft bearing;

- Checking the propeller shaft installation;

- Inspecting the propeller shaft installation;

- Checking the propeller shaft bearing;

- Inspecting the propeller shaft bearing;

- Measuring the straightness;

- Measuring wear of the propeller shaft bearing bushes;

De Wiel Services Alignment is part of De Wiel Services World Wide On-Site Machining.

This means that, just like with World Wide On-Site Machining, we are available for our customers worldwide to check the stern tube or to make various other measurements on the propeller shaft installation.