Onsite Boring

Onsite Boring

De Wiel Services World Wide On-Site machining has been active worldwide in all types of mobile machining for 50 years, also called on site machining. Our company has a wide range of mobile machining machines, including a variety of mobile boring machines.

5 reasons for choosing for on-site machining:

- Your product cannot be machined in a machine factory.

- Your product is too big and heavy to transport by road

- You think the transport costs to transport your product by road are too high

- You think the waiting times at the machine factory are too long

- You want a shorter delivery time of your product

- You want to continue working on your own product during on-site machining

In those cases, you choose for “DE WIEL SERVICES WORLD WIDE ON SITE MACHINING”

This means:

- Highly skilled engineers

- The highest quality

- Short turnaround time

- Friendly service

- Customer focus

- HSE certified services

Our machines are transported to the customer by truck, sea container or plane. Our engineers come to you on site with the relevant machines, align them, and then machine the product according to the drawings you provide. Together with you, we guarantee a satisfactory result for you.

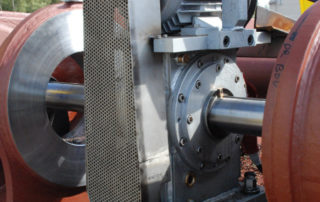

We have a wide range of on-site machines. Whether it is for mobile boring, mobile milling, mobile turning, drilling and tapping, reaming and honing. In most cases, De Wiel Services has a fitting solution. We also offer training, advice and construction supervision services.

Our specialists and advanced machine tools offer complex on-site machining solutions in industrial environments anywhere in the world. With on-site machining, you avoid the high costs for removing, transporting, reassembling your machines and machine downtime.

Our special On-site machining department focuses entirely on mobile machining. All our mobile machines are set up by our own engineers, using advanced laser measurement techniques.

This saves you extra costs for setting up and aligning. In addition, it is always possible to carry out intermediate quality checks and final reports during the work. In most cases, we are able to meet our customers’ demands.

No standard solution available? Then we look for a solution together with our customer. Our many years of experience and craftsmanship ensure that we can provide specialist services.

We can do the following at your premises:

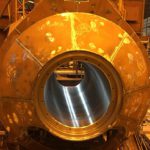

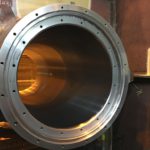

- Internal mobile boring up to a diameter of 4 meters.

- External mobile boring up to a diameter of more than 4 meters.

- Mobile surfacing, up to a diameter of 6 meters.

- Line drilling, up to a distance of 50 meters.

Line drilling is unique. We are able to drill in a line over distances of up to 50 meters. De Wiel Services is specialised in mobile machining of all types of stern tubes sleeves.

Your demand is our challenge!